With the transformation and development brought about by electrification, intelligence, and lightweight, the number of wire harnesses as the main network of circuits in the three major fields of automotive, industrial, and electronic is increasing, and the performance requirements are also getting higher. As the identity identifier of wire harnesses, wire harness labels are also given more special requirements.

For example, car wiring harness labels need to have characteristics such as heat resistance, oil resistance, and cold resistance; At the same time, he needs to be able to adapt to high mechanical strength and high-temperature environments for use. In addition, with the development of intelligence, cars are no longer just a row of sofas on top of an engine. Cars are not just means of transportation, but also a complex computer with the function of connecting everything for office and entertainment. Therefore, the electrical performance requirements of car wiring harnesses for wires, labels, clips and other auxiliary materials are also increasing. With the popularization of new energy vehicles, automotive wiring harnesses have been pushed into an era of rapid and high-quality development. At the same time, in order to avoid safety hazards caused by short circuits in wiring harnesses, more brand terminals have put forward higher requirements for fire prevention and flame retardancy.

Main features:

1. Waterproof, stain resistant, scratch resistant, not falling off, not changing color

2. Good adhesion and durability

3. Has good resistance to high temperatures, friction, and chemicals

4. Can be pasted on rough, irregular, and "difficult to adhere" surfaces

5. Characteristics of low fire hazards

6. Has high flame retardancy and excellent flame resistance characteristics

7. It can also resist corrosion from major industrial and military grade fluids (as defined by RW-2513)

8. The average outdoor lifespan can reach 5-8 years

Different industries have different demands for wire harness labels:

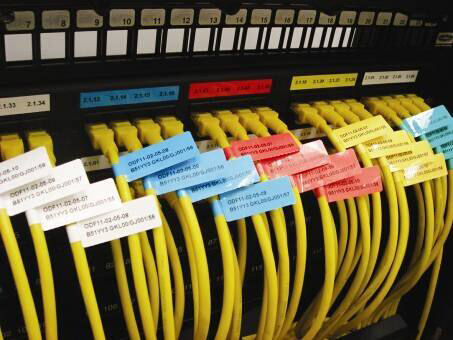

Cable labeling method:

Labeling requirements: The wrapping should not curl up, the adhesive should not open, or the opening should be less than 2mm

Label structure: In the cable bundle industry, there are significant differences in the selection of cable labels due to different terminal requirements. There are various solutions such as copperplate paper lamination, synthetic paper, pearl film, PET, etc. From the perspective of labeling methods, there are mainly two types: adhesive and winding.

Wire harness label

people have paid

Price:

¥ -

Stock:

0

Number:

-

+